This custom-made Universal hardness tester with a force range of 500gf – 3000kgf covers all hardness scales: Vickers (+ HVD), Knoop, Brinell (+HBD) & Rockwell.

The motorized descending test head is equipped with a 9 position turret and accommodates:

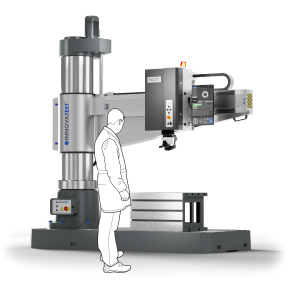

The IMPRESSIONS™ 4 full tester and configuration control can be easily operated by means of the 22’’ HD touchscreen. Due to the enormous workpiece accommodation of 1500mm (H) X 1500mm (D), the NEMESIS 9800G2 is perfectly suitable for heavy and very large parts.

The second Z-axis has a 125mm stroke descending test head and a 1500mm horizontal stroke offering unique flexibility.

Scales: Rockwell, Superficial Rockwell, Brinell, Vickers, Knoop

Test Forces: 500gf – 3000kgf (multi load cell, closed loop)

Camera: 18 Megapixels, Full HD camera system, with zoom and auto-focus

Overview Camera: Full HD optical zoom stage overview camera

Objectives: 0.7X, 2.5X, 5X, 10X, 20X

9 Position Turret: 9 position tool changer (turret) with visual LED process indicators

Control: Fully integrated i7 Controller, Windows 10 operated, 22” industrial touchscreen, IMPRESSIONS™ advanced workflow software, includes automatic measurement, stage control & pattern configurator, key board & mouse

Illumination: Power LED

Workpiece Acc.: 1500mm (H) X 1500mm (D)

Output: USB, LAN, Bluetooth

Software: Large choice of software options, features, plug-ins and add-ons, Q-DAS certified