Scroll down

![]()

–

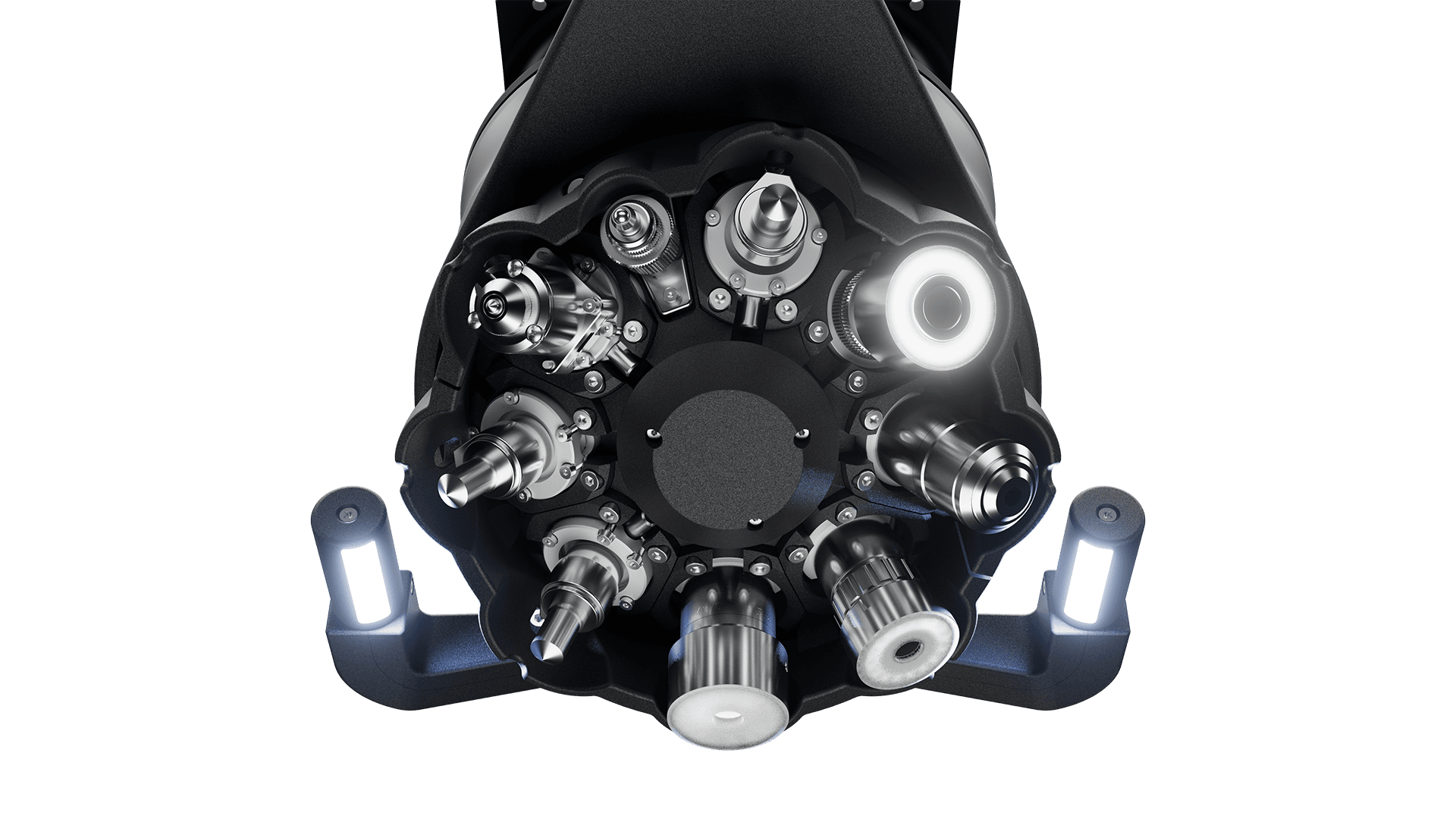

The second generation of the FALCON 5000, the G2, Micro Vickers / Vickers / Knoop and Brinell hardness tester provides exceptional performance, designed to match the most demanding user tasks. The FALCON 5000G2 contains a revolutionary force application range and renewed optical system. The all new 9 position tool changer (turret) accommodates to a wide range of indenters,

FORCE RANGE:

![]()

indenter actuators with load cells, objectives, a cross-laser positioning system and a load cell supported touch probe. It also provides a base to the 18 megapixel full color measurement camera and 18 megapixel full color overview camera with variable field of view, motorized zoom and auto focus system.

–

Just buy a software release ticket, and your tester has added functionality, regardless where it is located. A revolutionary system taking care of all your needs. In this way we keep the learning curve, the process to work efficiently with our software limited to the level of ‘’need to have’’ and ‘’need to know’’. The proportion of installed and activated software never needs to be more than your requirements.

Unique to IMPRESSIONS™ 4 is a choice for screen size and position. Whether you wish your interface to be in portrait mode or landscape, all functionality is supported in both positions. For table top solutions like testers in laboratories, users often opt for landscape screen(s).

For the FALCON 5000G2, INNOVATEST recommends the 27’’ industrial quality landscape screen operated by both touch as well as mouse and keyboard. One screen is standard included with the hardness tester, optional is the Dual view function, these are 2 x 24’’ industrial quality landscape screens. New applications are added to IMPRESSIONS™ on a regular basis; while INNOVATEST provides 10 years free updates, upgrades to more functionality or new additions can be purchased at any time.

Newly developed 9 position state-of-the-art tool changer. From ‘’turret’’ to tool changer because the 5000G2 turret offers more than purely holding lenses and indenters. The high-speed rotating mechanism is prepared for future modular plug & play tooling development. The tool changer is fully configurable. Either 8 indenters or 8 objectives, or any combination, a laser positioning system and touch probe are installed as standard. The standard (removable) skirt protects tooling from damage.

The LED bars on the front of the tool changer continuously inform you about the device status. The range of flash intervals and color codes (red, blue, green) indicate the process mode of the tester; red: automatic operation, (busy & hands off), blue: in single test procedure; or green: idle, ready for next task.

|

||||

| 9-Position tool changer | Cross laser & touch probe |

Protection skirt | ||

|

|

|

||

| Collision detection system | Crystal clear ringlights | Stage illumination | ||

The FALCON 5000G2 has an iSMART™ docking station for the quick mounting of workpiece platforms. The docking station allows a wide variety of test tables, anvils, manual XY stages and the new wireless iSMART™ motorized CNC X-Y stages to dock within seconds. In this way, the user can create the most ideal circumstances for his particular workpiece.

The docking station is a new INNOVATEST standard. It can be found on an increasing number of hardness testers. This means that you can change your fixtures, stages, anvils and even the wireless iSMART™ motorized CNC X-Y stage between the various machines in your possession. No need to duplicate expensive tooling for different machines. The iSMART™ docking station provides communication identification and power supply to various mounted accessories.

The new wireless (or wired) iSMART™ motorized CNC X-Y stages provide excellent specifications combined with maximum flexibility. This new technology allows you to purchase a standard machine to start with, add stages, change dimensions of motorized CNC stages according to new requirements later in the life of the tester and upgrade in just seconds!

iSMART™ technology reduces possible down time on stage maintenance to seconds in case of calamities. While most automatic machines will be ‘’out of service’’ if the stage is defective, a wireless iSMART™ stage can just be exchanged in seconds. No downtime! There is a choice of 7 different type of iSMART™ stages and if you need larger dimensions or different specifications for Custom Products, we can manufacture any possible stage to your requirements.

More about the FALCON 5000G2?

Visit the product page for more detailed specifications, or click the ‘Configure Now’ button below and start configurating your FALCON 5000G2!