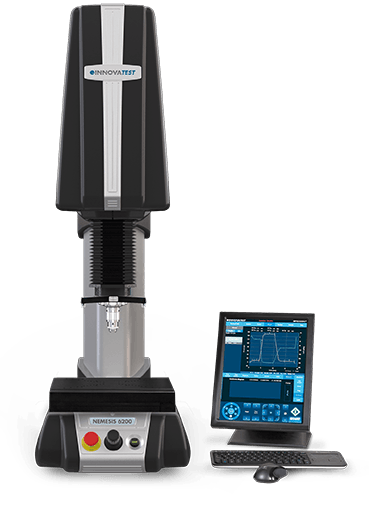

The 6200 Series hardness tester is a state-of-the-art machine. It features an all linear force application system, with a descending test head and a fixed work piece position. This eliminates, for 100%, any unwanted tolerance in the depth measurement.

The 6200 model features Load cell, force feedback, closed loop system, fully automatic, servo motor driven. This hardness tester can accommodate a wide variety of applications due to the IMPRESSIONS™ advanced hardness software.

Perfectly suitable for aircraft engine parts, automobile parts, production lines, general quality assurance and the highest standard for laboratory use.

Scales: Rockwell & Superficial Rockwell, Brinell (RSB models)

Test Forces: 3, 10kgf pre-load; 60, 100, 150kgf main load. All Brinell test forces from 1kgf – 250kgf (RSB models)

Load App. System: Fully automatic, Load cell, closed loop, force feedback

Control: Fully integrated Windows Controller, SSD hard disk, Windows 10 operated, IMPRESSIONS™ advanced workflow software, includes automatic measurement, keyboard & mouse

Display: 15” full colour touchscreen

Advanced Output: Multi USB, CSV files, single readings, reports, printer, Q-DAS certified

Laser: Built-in laser positioning system

Software: No. of tests, Mean, St. Deviation, Min., Max., Range, CP, CPk, individual readings list, storage memory, Dwell time, test force setting, scale selection, calibration etc

Illumination: Adjustable workpiece illumination

Z-Axis: Descending test head, with collision detection, CNC motorized, ball bearing spindle, with fast up down and joystick for fine adjustment

XY-Stage: Manual, motorized stages (6200) or/and anvils or work tables at choice

Workpiece Acc.: 345mm (H) X 220mm (D)